Multichannel solutions for smart customer dialogue

14 January 2024

Door opening systems for supercars

15 January 2024

Multichannel solutions for smart customer dialogue

14 January 2024

Door opening systems for supercars

15 January 2024

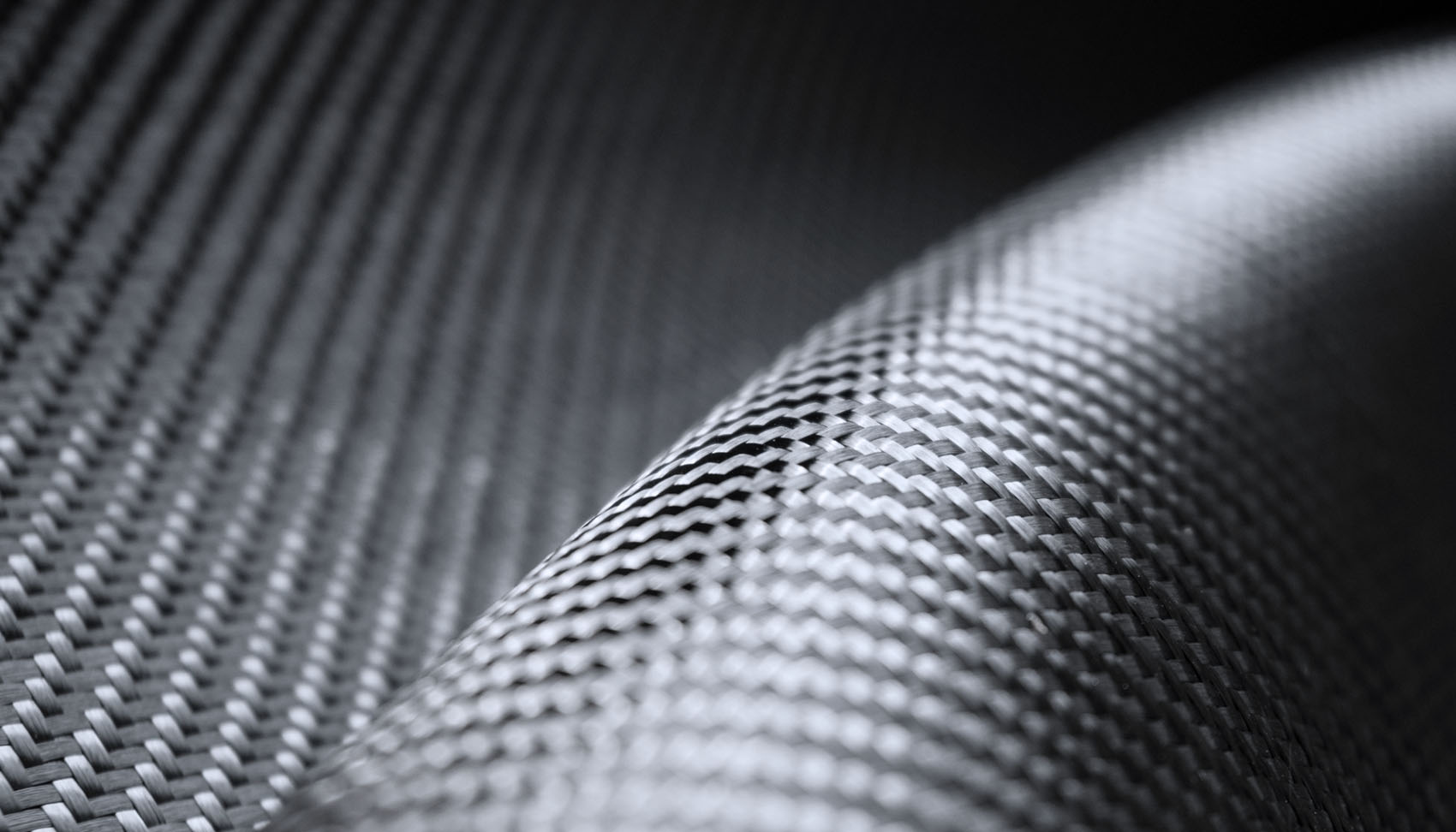

Development of automotive components with composite materials

The use of composite materials in the automotive industry is becoming increasingly important.

Fiberglass, Kevlar, carbon and hybrids, initially developed for use in aviation, have long found employment only in motorsport.

For a long time, despite the obvious advantages in terms of weight and mechanical properties, the spread of these materials on production cars was slowed by high production costs and perceived poor quality.

The spread of composite materials on cars in every segment.

The development of technologies and the adoption of specific processes for use in the automotive field, as well as growing experience on the part of designers, have led to increasingly widespread use of composite materials, not only in supercars, but also on large production cars. Low tooling costs and the need to reduce fuel consumption and emissions have allowed them to spread widely on cars in all segments.

Today an automotive designer must be able to develop indifferently sheet metal, plastic or carbon components, mechanical joints or bonding, constant or variable thickness elements, isotropic or anisotropic structural parts.

IPer designers have never been more important to keep up-to-date in an industry that is constantly and rapidly evolving.

MGE can provide extensive experience in the development of automotive projects that include the use of these high-performance materials, suggesting and developing solutions consistent with the technologies that will be used in the subsequent production phase.

Why turn to MGE?

Our Know-How in the automotive field allows us to suggest and develop solutions that include the use of high-performance materials consistent with the technologies that will be used in the next stage of production.